Add Products From Inventory To The Job Sheet Easily Using The Part Number

Last Updated: 30 December 2024

Effortless Job Sheet Management: Adding Inventory Products Using Part Numbers

In the fast-paced world of repair services, maintaining accurate job records and seamless inventory management is critical to ensuring operational efficiency and delivering exceptional customer satisfaction. Repair jobs often involve multiple components, and the ability to track these parts accurately can make or break your business operations. With our repair management software, linking inventory products to job sheets using part numbers becomes a streamlined and efficient process. This powerful feature not only simplifies your repair workflows but also ensures accurate billing and keeps your inventory records consistently up to date.

Gone are the days of manually cross-referencing parts or risking billing inaccuracies due to human error. By utilizing part numbers, repair technicians can effortlessly identify, add, and manage the required components directly within the job sheet. This functionality ensures your team spends less time on administrative tasks and more time on high-value repair work, increasing overall productivity and efficiency in your operations.

Why Part Numbers are Critical in Repair Operations

Part numbers are the backbone of any effective inventory management system in the repair industry. These unique identifiers are assigned to each item in your inventory and provide unparalleled precision in tracking and managing stock. By replacing generic product descriptions with part numbers, you eliminate confusion, especially when dealing with items that may have similar names or functions. Whether you’re managing spare parts for electronic repairs, automotive servicing, or appliance maintenance, part numbers ensure your team can quickly locate and utilize the exact parts needed for a specific job.

For example, when a repair technician is working on a laptop screen replacement, having the correct part number ensures they select the precise screen model required for that device. This reduces the chances of errors, such as using incompatible parts, which could lead to additional costs or delays. Additionally, the use of part numbers supports better accountability and transparency across your repair operations, as every part used is systematically tracked and recorded.

Step-by-Step Guide to Adding Inventory Products to Job Sheets

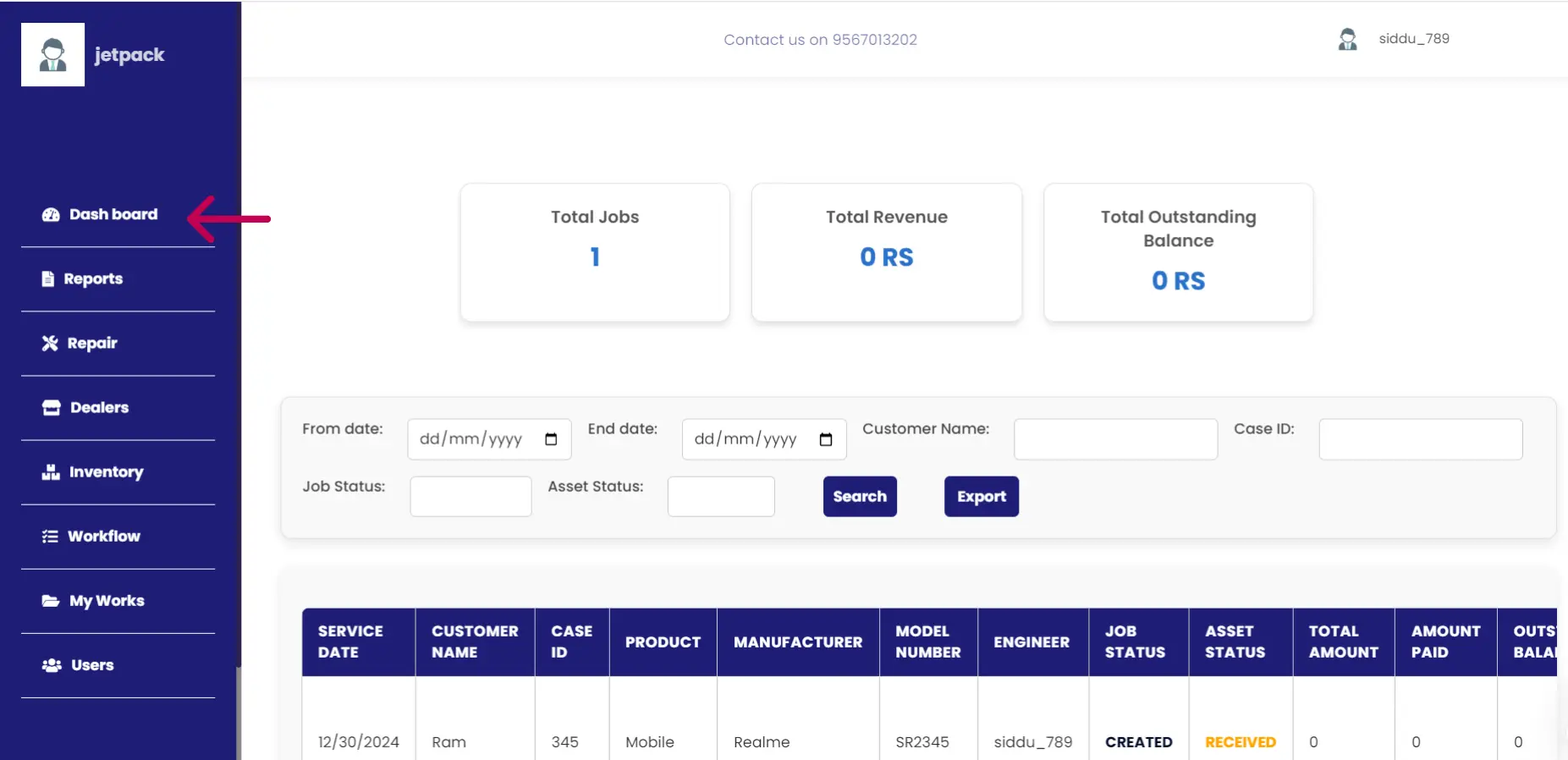

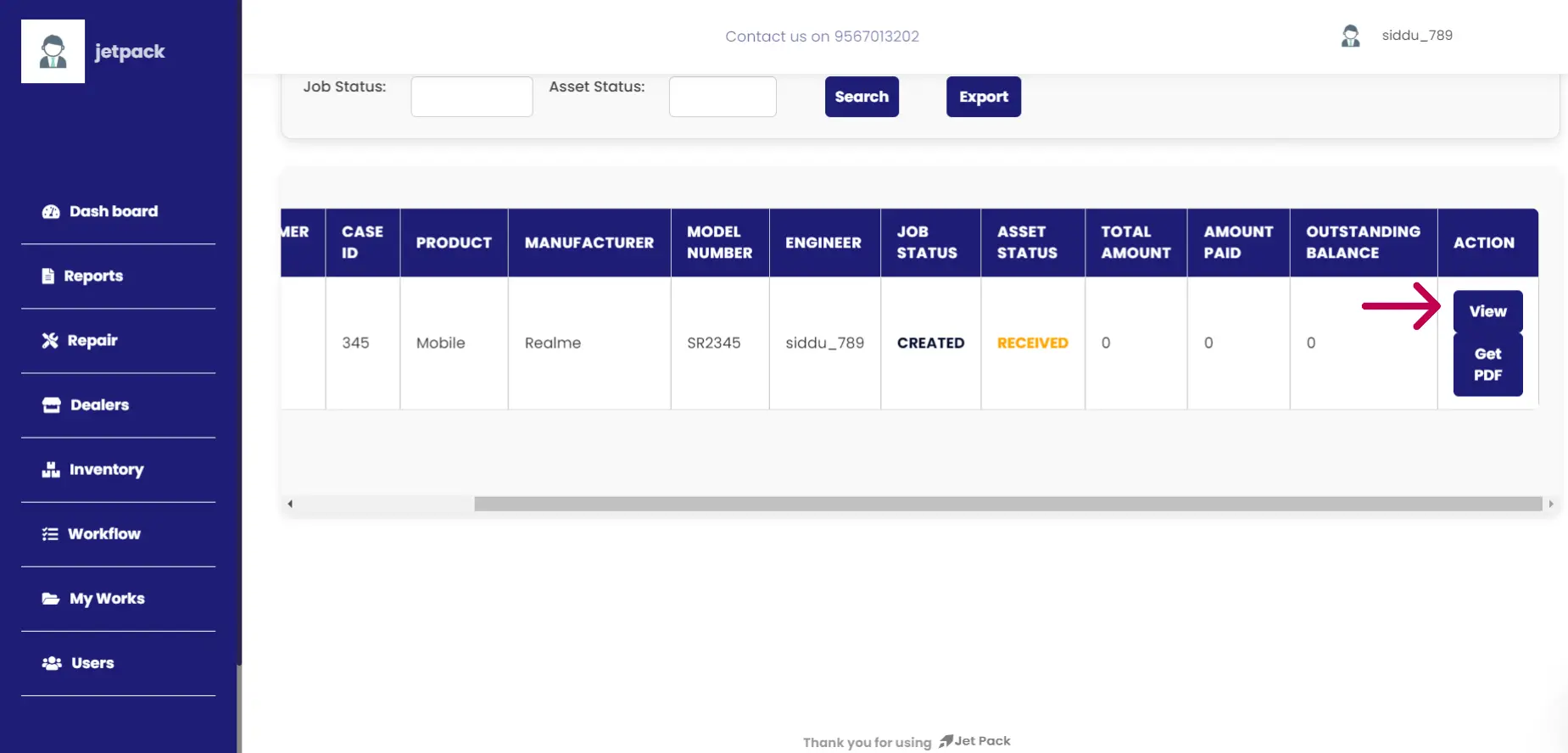

Step 1: Navigate to the dashboard of your repair management software. From there, select the specific job sheet where you want to add inventory items. The job sheet is a central document for each repair job, detailing the services performed and parts used.

Step 2: Within the job sheet interface, locate the "View" section. This feature allows you to seamlessly integrate items from your inventory with just a few clicks.

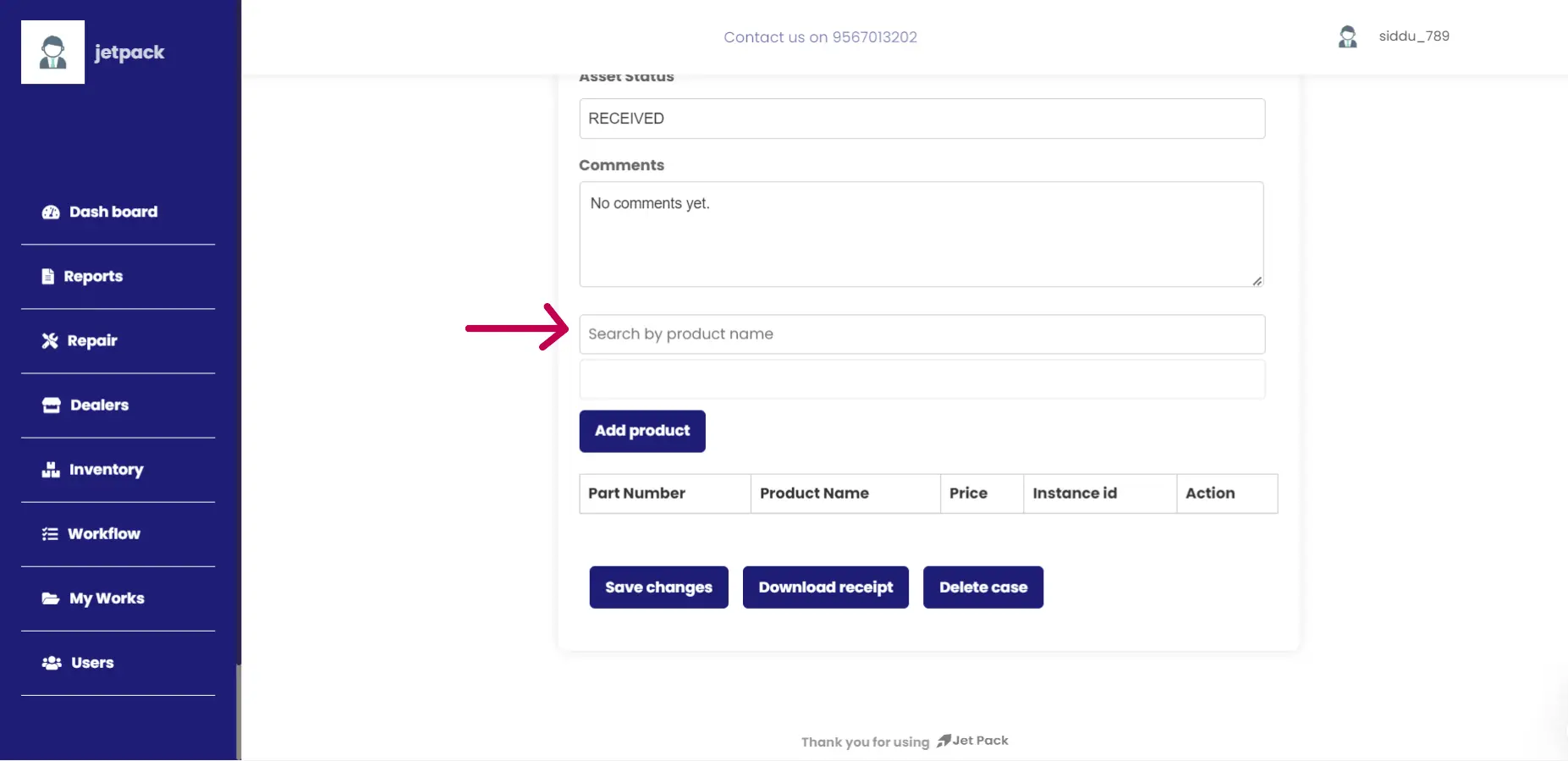

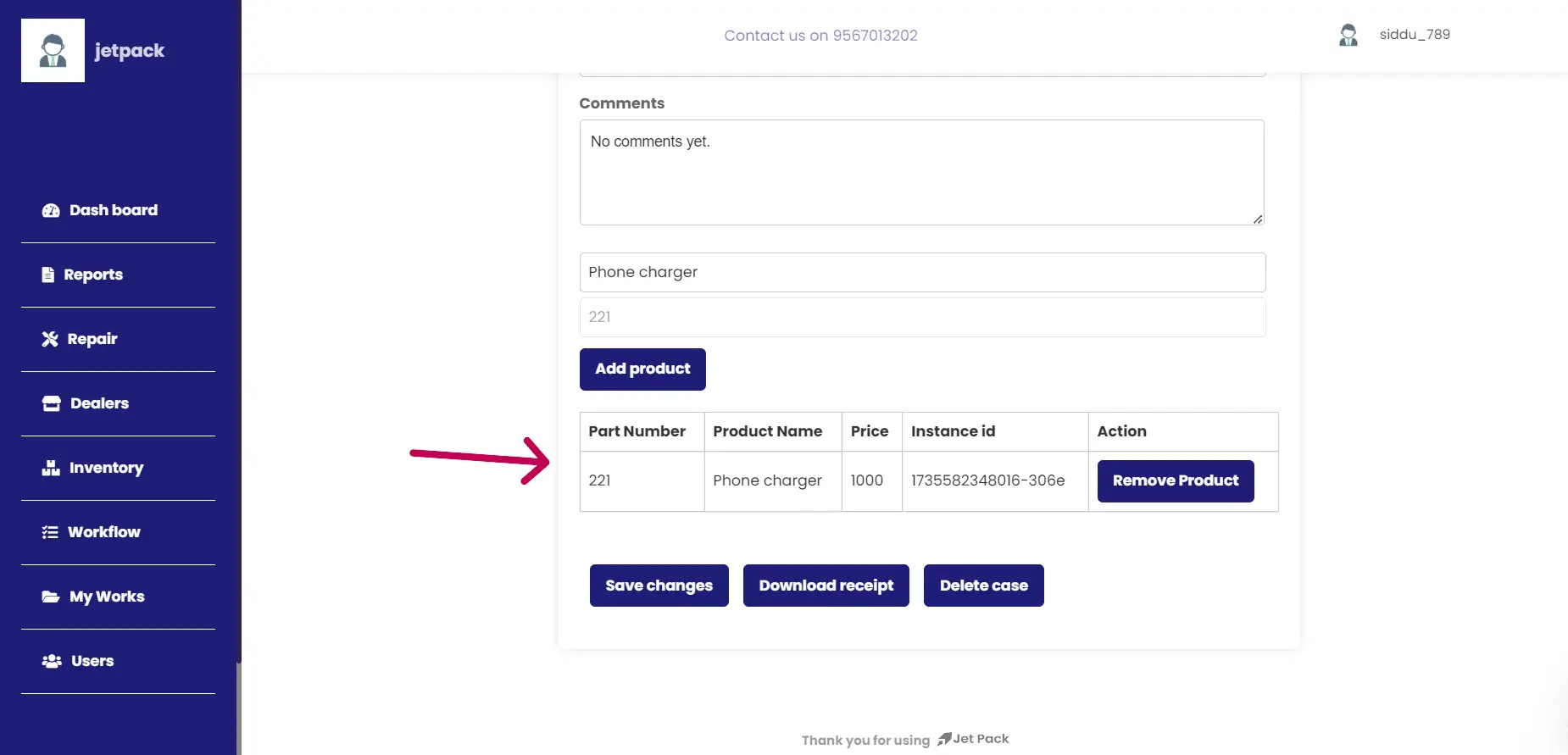

Step 3: Use the part number field to input the unique identifier for the product you wish to add. The system will automatically search the inventory database and retrieve the corresponding item. This ensures accuracy and eliminates the need for manual product searches.

Step 4: Once the item is retrieved, review its details such as name, price, and quantity available in stock. Confirm the selection to add the product to the job sheet.

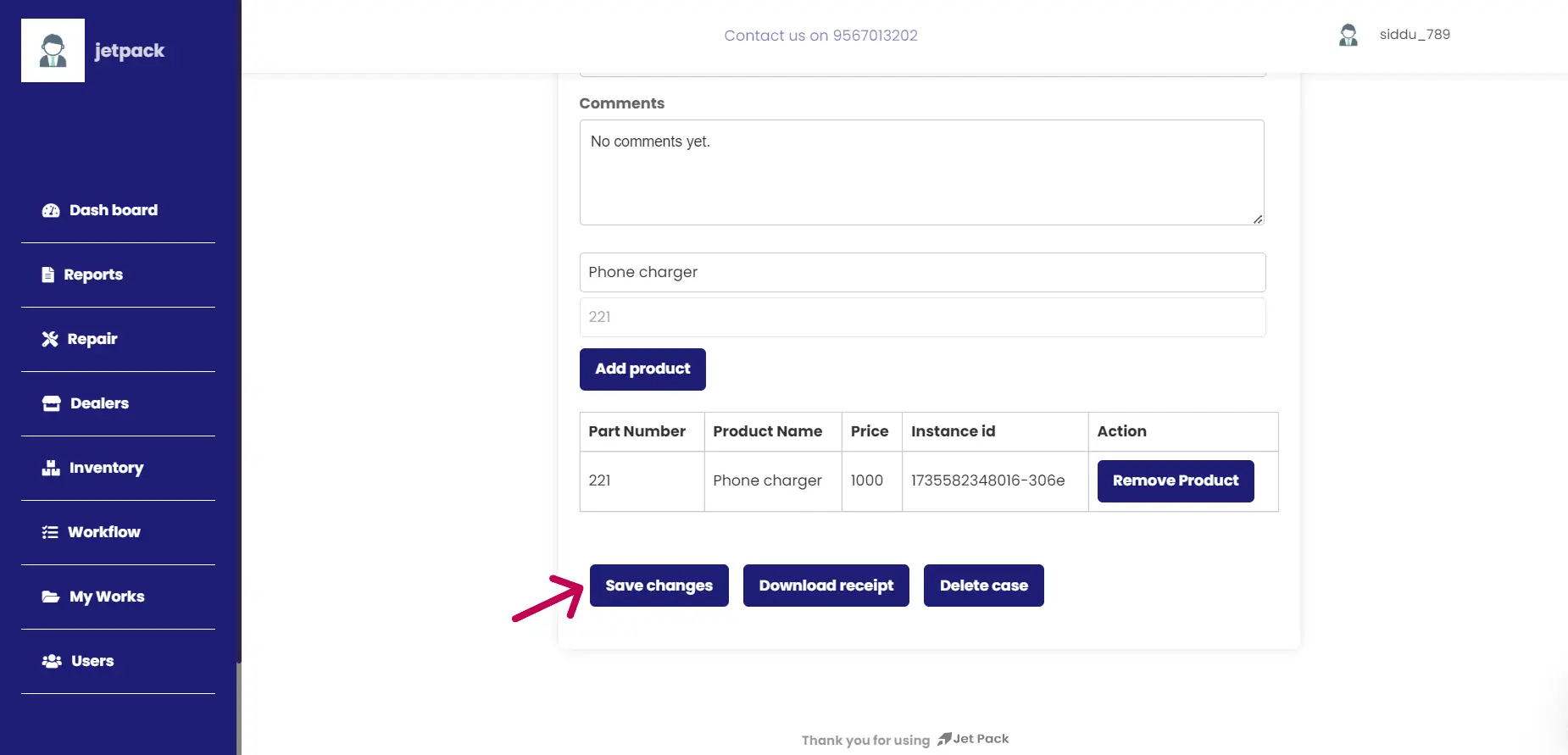

Step 5: When the product is added to the job sheet, the system will automatically adjust your inventory records, deducting the quantity used. This real-time update ensures your stock levels are always accurate, helping you avoid shortages and overstocking.

Key Benefits of This Feature

- Enhanced Accuracy: Part numbers eliminate errors caused by manual data entry or product misidentification.

- Faster Workflow: Technicians can quickly add parts to job sheets without navigating through long lists of inventory items.

- Improved Accountability: Every part used is logged and linked to a specific job, ensuring transparency in billing and inventory usage.

- Streamlined Stock Management: Real-time inventory updates keep your stock records precise, enabling better forecasting and restocking decisions

Visualizing the Process

Imagine an intuitive inventory page seamlessly integrated within the job sheet interface. Each item is displayed with essential details, such as the part number, serving as a unique identifier for each product, and the product name, providing a clear description of the item. The page also includes the price of each part to aid in accurate billing, stock availability to display the remaining quantity in inventory, and usage history to record jobs where the part has been used. This comprehensive feature ensures that the entire process, from selecting parts to updating inventory, remains intuitive and error-free.

Why It Matters for Your Repair Business

By seamlessly connecting inventory management with job sheet creation, this feature reduces administrative workload and enhances operational efficiency. Whether you’re a laptop repair technician, a mobile service expert, or managing a comprehensive repair shop, this integration empowers you to focus on delivering top-notch service without worrying about manual stock adjustments or billing errors.

Take Control of Your Repair Workflow

Streamline your repair process with our inventory integration tools. From accurate tracking to seamless job sheet management, our software is designed to simplify the complexities of your business operations.

Start leveraging this feature today and experience the ease of managing inventory and job sheets like never before!